We are a

plate rolling machine of bending machine equipment with over 10 years of industry experience.Today,we would like to introduce to you:

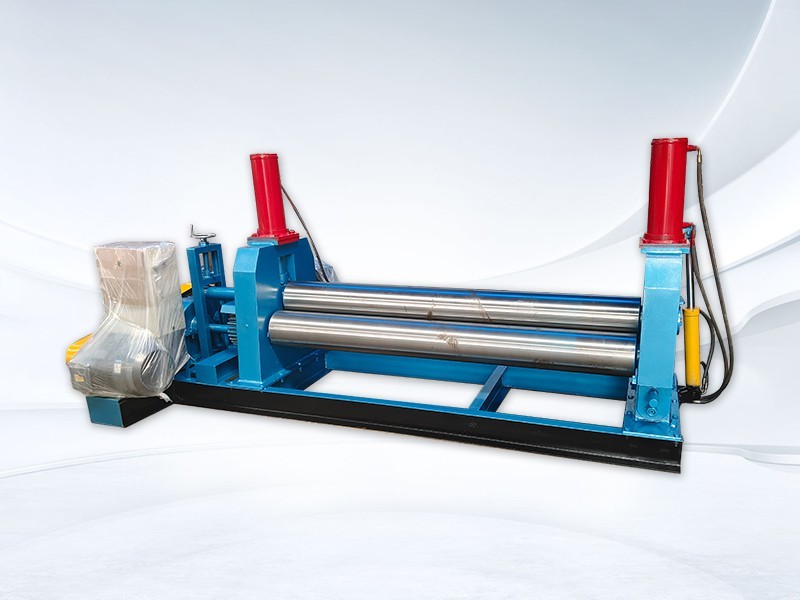

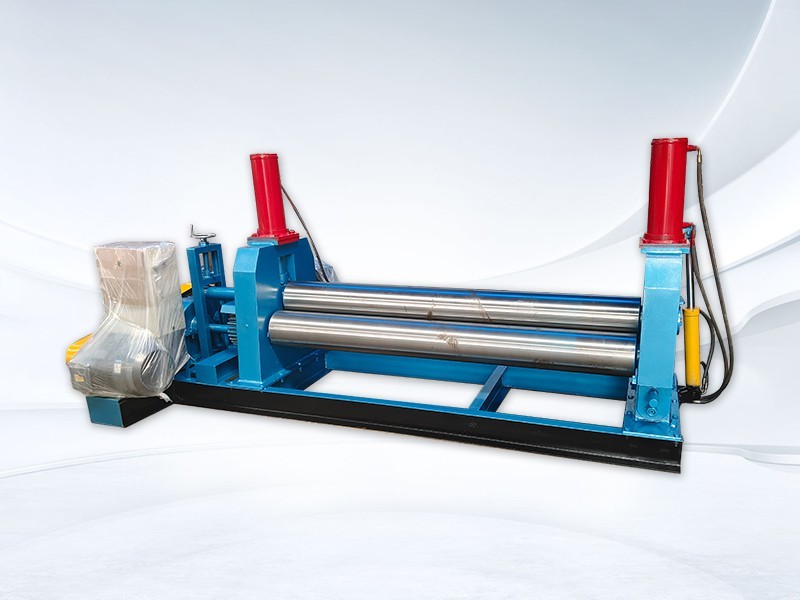

plate rolling machine is a mechanical equipment used to bend metal sheets into shape,widely used in industries such as shipbuilding,boiler manufacturing,chemical machinery,metal structures,and mechanical manufacturing.This product mainly consists of upper and lower rollers,frame,reducer,electrical components,unloading device,and base.Among them,the upper and lower rollers are important components of the plate rolling machine,usually made of forged high-quality carbon steel.The rack supports the entire equipment and is equipped with lower roller bearings,forming a whole.Its working principle mainly includes the following aspects:

1.Movement of upper and lower rollers

The upper roller of the plate rolling machine is located at the center symmetrical position of the two lower rollers,and can be vertically lifted and lowered by the hydraulic oil in the hydraulic cylinder acting on the piston.This vertical lifting and lowering motion is achieved by the final gear driving the two lower roller gears to mesh and rotate,thereby providing the necessary torque for rolling the plate material.

2.Working process

The plastic metal plate with flat specifications is continuously bent through multiple passes by the three working rollers of the plate rolling machine,between two lower rollers and one upper roller,with the help of the downward pressure of the upper roller and the rotational motion of the lower roller.During this process,the inner layer of the metal plate undergoes compression deformation,while the middle layer remains largely unchanged.The outer layer undergoes tensile deformation,resulting in plastic deformation,and is rolled into the required cylinder,cone,or part thereof.

The application scope of this product is very wide,not limited to traditional manufacturing industries,but also includes modern high-tech industries.For example,plate rolling machines play an important role in manufacturing pressure vessels,aerospace components,etc.When selecting,it is necessary to consider the type and thickness of materials to ensure that the equipment can meet specific processing requirements.

In short,the plate rolling machine uses the coordinated motion of the upper and lower rollers to produce plastic deformation of the metal sheet through hydraulic or mechanical force,thereby achieving the bending and forming of the sheet.This process involves complex mechanical principles and technical details,and is one of the essential key processes in modern manufacturing.

If you are interested in the bending plate rolling machine,please contact us.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com