1、Machine model name

Model: 12x1200 One-time forming hydraulic cone rolling machine

Image(For reference only):

2、 Main parameters

3、 Introduction to Machine Structure

The hydraulic control upper roller vertical adjustable plate rolling machine has a circular rolling function. Its main structure consists of a main transmission device, an upper roller device, and other components. The entire machine has a compact structure, reliable use, and easy maintenance.

The lower roller of this machine is a fixed position active roller, which is transmitted from the main motor to the input shaft of the main reducer through a set of couplings, and then transmitted to the two lower rollers through the output shaft to rotate the lower roller. The upper roller is the active roller, and its up and down movement is driven by the top hydraulic cylinder on the frame. When the rolled workpiece is tied up, the upper roller moves to the middle position between the two lower rollers and rises to the set height. After unloading the workpiece, one working cycle ends.

When the upper roller moves downward to press the sheet metal, friction is generated between the sheet and the stick, and the lower roller rotates to feed the sheet metal. The arc can be formed by the three tangent points where the three rollers are in contact with the metal plate, and the descent degree of the upper roller can be controlled to achieve the desired curvature radius of the arc.

3.1. Feed the metal plate in so that it passes over the center of the second lower roller, paying attention to keeping the side of the metal plate perpendicular to the center axis of the lower roller.

3.2. After the upper roller descends to the appropriate position, drive the lower roller to curl the steel plate. Note that one end of the steel plate cannot detach from the other lower roller.

3.3. Repeat the same process for the first curl until the desired curl diameter is reached.

3.4 Unloading:

(1) Activate the upper roller lift cylinder.

(2) Remove the rolled and formed workpiece.

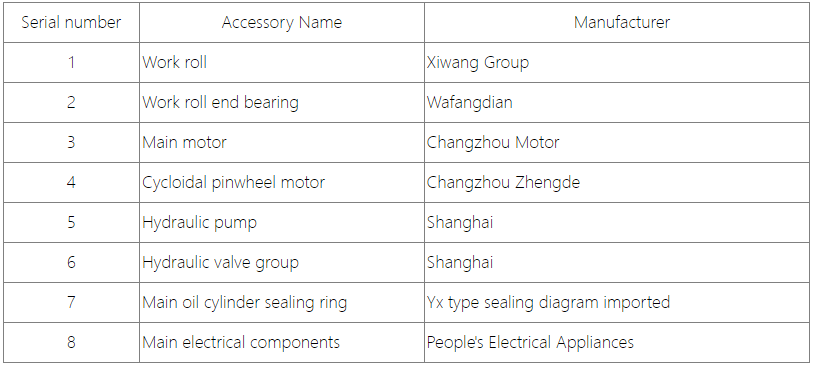

4、List of Main Purchased Parts

Roller material: 45 # steel that has undergone quenching and tempering heat treatment, with a one-year equipment warranty.

If you need a cone rolling machine or are interested in a cone rolling machine, please provide the material of the plate, the thickness of the plate, the diameter of the cone small opening, the diameter of the cone large opening, the vertical height or diagonal side length of the cone, and we will recommend a suitable machine model for you.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com